Description

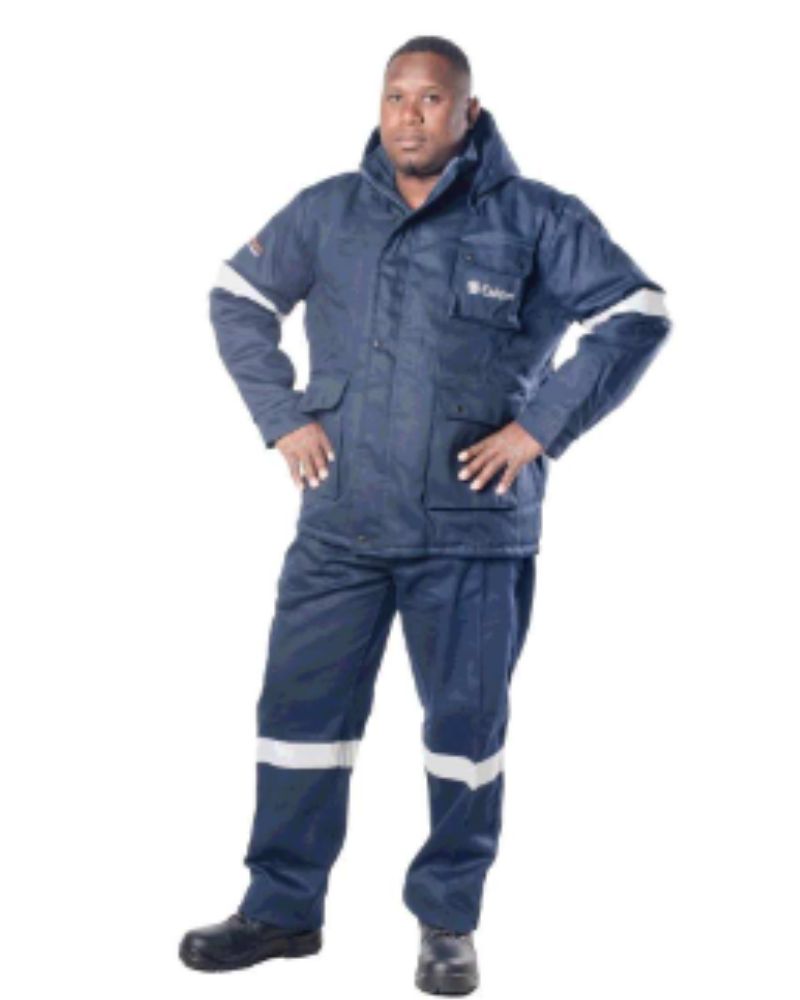

Dromex® D59, ESKOM specification, 100% locally manufactured flame treated thermal winter jacket is designed to protect the user from the hazards of accidental flame contact, reducing injury and loss of life when working in hazardous environments.

This jacket is suitable for use in colder work environments, keeping the user warm whilst the 100% cotton satin weave finish and natural fibre construction makes this garment comfortable and breathable.

The D59 drill fabric construction is heavy duty and durable whilst the flame treatment technology resists the effects of flame contact, offering the user essential protection in the workplace.

This garment consists of the following:

• A detachable flame retardant hood with press stud attachment.

• A high stand collared jacket with internal hanger loop.

• Eskom pantone navy blue colour specification.

• High visibility flame retardant reflective tape on upper arms for enhanced visibility when working in poor lighting environments.

• Storm flap with snap button closure and a concealed chunky nylon YKK open end zip.

• 2 Large waist pockets with press stud closure flaps and open side entry pockets.

• Bellow chest pocket with flap, nylon press stud closure and Eskom emroidered logo.

• Sleeve cuffs have an adjustable strap with 2 position snap fastening allowance and nylon press studs.

• Zero harm embroidery on right arm.

This jacket is suitable for use in general work environments such asengineering, smelting operations, mining, construction, oil and gas, petroleum, maintenance and repairs and welding industries. Suitable for use at all Eskom divisions, Generation, Transmission, Distribution and Rotek.

This jacket is suitable for use in colder work environments, keeping the user warm whilst the 100% cotton satin weave finish and natural fibre construction makes this garment comfortable and breathable.

The D59 drill fabric construction is heavy duty and durable whilst the flame treatment technology resists the effects of flame contact, offering the user essential protection in the workplace.

This garment consists of the following:

• A detachable flame retardant hood with press stud attachment.

• A high stand collared jacket with internal hanger loop.

• Eskom pantone navy blue colour specification.

• High visibility flame retardant reflective tape on upper arms for enhanced visibility when working in poor lighting environments.

• Storm flap with snap button closure and a concealed chunky nylon YKK open end zip.

• 2 Large waist pockets with press stud closure flaps and open side entry pockets.

• Bellow chest pocket with flap, nylon press stud closure and Eskom emroidered logo.

• Sleeve cuffs have an adjustable strap with 2 position snap fastening allowance and nylon press studs.

• Zero harm embroidery on right arm.

This jacket is suitable for use in general work environments such asengineering, smelting operations, mining, construction, oil and gas, petroleum, maintenance and repairs and welding industries. Suitable for use at all Eskom divisions, Generation, Transmission, Distribution and Rotek.

Specifications

Style: Triple layer, 5 pocket long sleeve thermal jacket with high visibility reflective tape on arms.

Available in Navy Blue.

Fabric composition: 100% Cotton.

Mass: 315gsm Cotton fabric (Outer)

100gsm Flame retardent wadding

145gsm Cotton lining (Inner)

Reflective: 50mm Silver flame retardant tape.

Style: Triple layer, 5 pocket long sleeve thermal jacket with high visibility reflective tape on arms.

Available in Navy Blue.

Fabric composition: 100% Cotton.

Mass: 315gsm Cotton fabric (Outer)

100gsm Flame retardent wadding

145gsm Cotton lining (Inner)

Reflective: 50mm Silver flame retardant tape.

Compliance & Conformity

• Eskom Personal Protective Equipment (PPE) Specification 240-44175132, D59 Flame retardant thermal jacket constructed from locally produced DA GAMA SANS approved 1387 flame reatadant fabric.

• The fabric is to SANS 1387-4 for D59 drill fabric, 4/1 satin weave @270gsm, 37 thread per cm weft and 19 threads per cm warp. The breaking strength is 940 N warp and 510 N weft.

• Flame retardant fabric is tested to SANS 1423-1 for textile fabrics of low flammability for apparel:

Class B Category 1:

The fabric ignites within a given time period and might continue to flame but at a rate of flame propagation that is within a specified limit.

Surface Flash None.

Ignition time (seconds) _ 20 sec.

Rate of flame propagation 5mm/s.

** Note this is a test situation for the fabric and does not cancel or imply otherwise to the labels wash instruction.

• Flame retardant silver retro-reflective tape is tested to SANS 50471:2006 (EN471:2003 + A1:2008) and SANS 1423-1:2008 for textile fabrics of low flammability for apparel:

High visibility warning protective clothing capable of signalling the users presence visually, intended to provide conspicuity of the user in hazardous situations under any light conditions by day and under illumination by vehicle headlights in the dark.

Performance requirements are included for retro-reflection and not for the entire garment.

• Eskom Personal Protective Equipment (PPE) Specification 240-44175132, D59 Flame retardant thermal jacket constructed from locally produced DA GAMA SANS approved 1387 flame reatadant fabric.

• The fabric is to SANS 1387-4 for D59 drill fabric, 4/1 satin weave @270gsm, 37 thread per cm weft and 19 threads per cm warp. The breaking strength is 940 N warp and 510 N weft.

• Flame retardant fabric is tested to SANS 1423-1 for textile fabrics of low flammability for apparel:

Class B Category 1:

The fabric ignites within a given time period and might continue to flame but at a rate of flame propagation that is within a specified limit.

Surface Flash None.

Ignition time (seconds) _ 20 sec.

Rate of flame propagation 5mm/s.

** Note this is a test situation for the fabric and does not cancel or imply otherwise to the labels wash instruction.

• Flame retardant silver retro-reflective tape is tested to SANS 50471:2006 (EN471:2003 + A1:2008) and SANS 1423-1:2008 for textile fabrics of low flammability for apparel:

High visibility warning protective clothing capable of signalling the users presence visually, intended to provide conspicuity of the user in hazardous situations under any light conditions by day and under illumination by vehicle headlights in the dark.

Performance requirements are included for retro-reflection and not for the entire garment.

Packaging, Storage & Obsolescence

Dromex® DW-D59ESKOM-WJ are packed in individual poly bags and sold as 5 jackets.

If there is visible damage such tears or burn holes it is recommended to replace the garment immediately.

Dromex® DW-D59ESKOM-WJ are packed in individual poly bags and sold as 5 jackets.

If there is visible damage such tears or burn holes it is recommended to replace the garment immediately.