Description

Dromex Promax C4000 Disposable Coverall

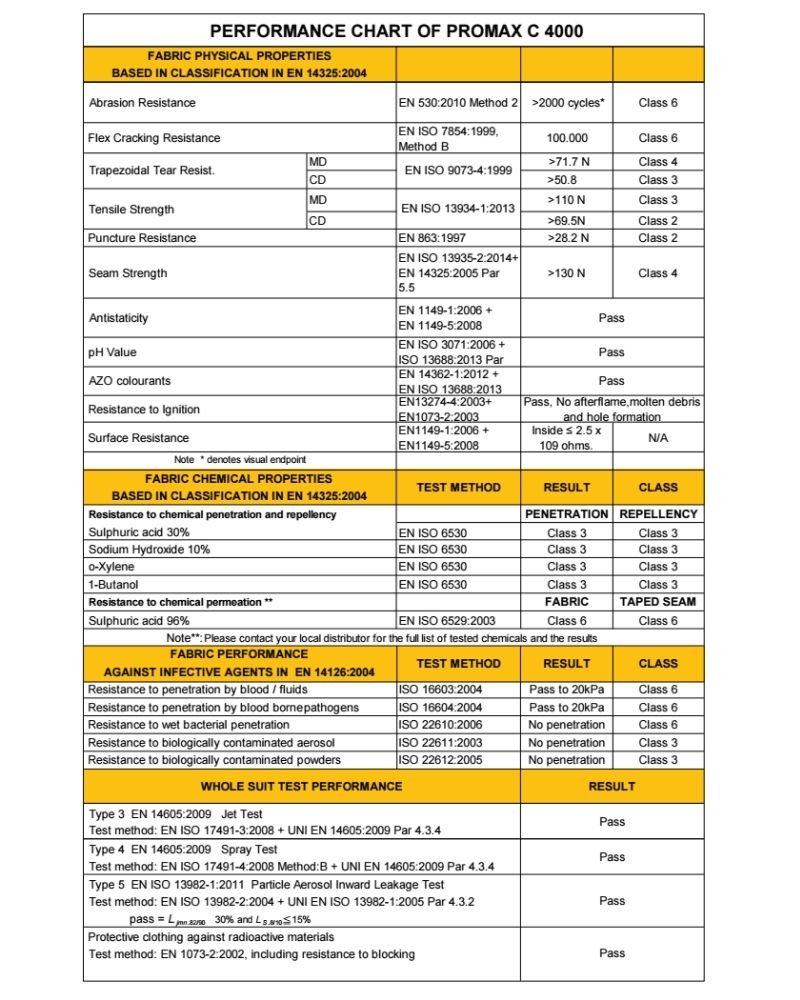

The Dromex Promax C4000 is a certified Type 3/4/5/6 disposable coverall designed to protect workers in hazardous environments such as chemical handling, spill response, contaminated sites, and biohazard exposure. Its multi-layer construction and sealed seams deliver reliable full-body protection while supporting comfort and mobility.

Key Features

- 🛡️ Certified protection: Type 3B, 4B, 5B, and 6B

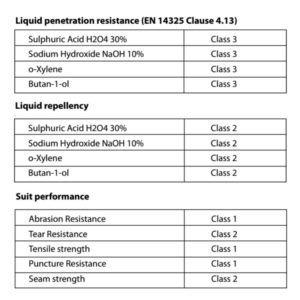

- 🔒 Ultrasonic welded and taped seams to help block dust and liquid ingress

- 🧵 Double zip with storm flap for secure front closure

- ✋ Double elasticated cuffs with thumb loops for a secure fit

- 🦵 Double‑layer cushioned knee pads for added durability and comfort

- 🧥 Elasticated hood, waist, and ankles for effective full‑body sealing

- ⚡ Antistatic properties and protection against particulate radioactive contamination

- 🟨 Yellow polypropylene/polyethylene fabric

Benefits

- 😌 Comfortable, ergonomic design supports longer wear during demanding shifts.

- 🚧 Helps maintain safety and focus in high‑risk applications.

- 🧪 Suitable for varied tasks—from chemical processing to spill cleanups.

Specifications

| Brand | Dromex |

| Model | Promax C4000 |

| Protection Types | Type 3B, 4B, 5B, 6B |

| Material | Yellow polypropylene & polyethylene foil, 88 g/m² (±2 g/m²) |

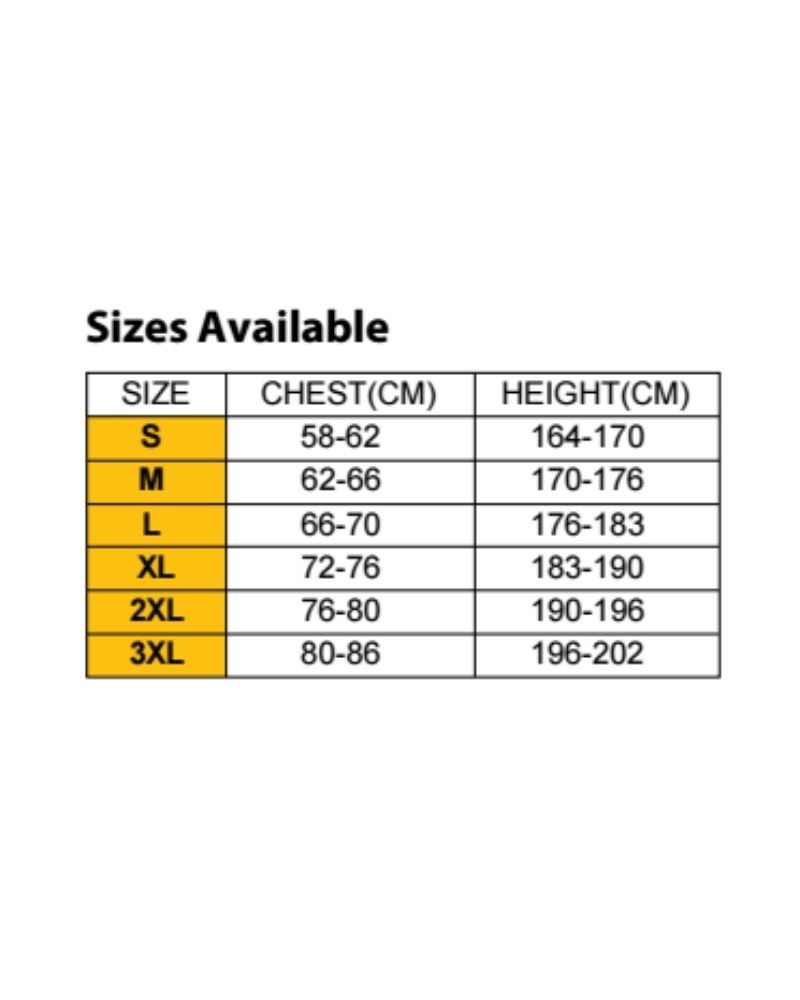

| Sizes | M–3XL |

| Seam Type | Ultrasonic welded and taped |

| Chemical Resistance (examples) | Sulphuric Acid 96% (Class 3), Sodium Hydroxide 10% (Class 3), o‑Xylene (Class 3), 1‑Butanol (Class 3) |

| Typical Applications | Chemical handling, spill response, contaminated area entry, oil & gas, tank cleaning |

How to Use

- Remove the coverall from packaging and unfold fully.

- Step into the legs and pull the suit up to your waist.

- Insert arms into sleeves and secure thumb loops.

- Zip the front and press the storm flap closed along its full length.

- Fit the hood and ensure all elastic edges are comfortably snug.

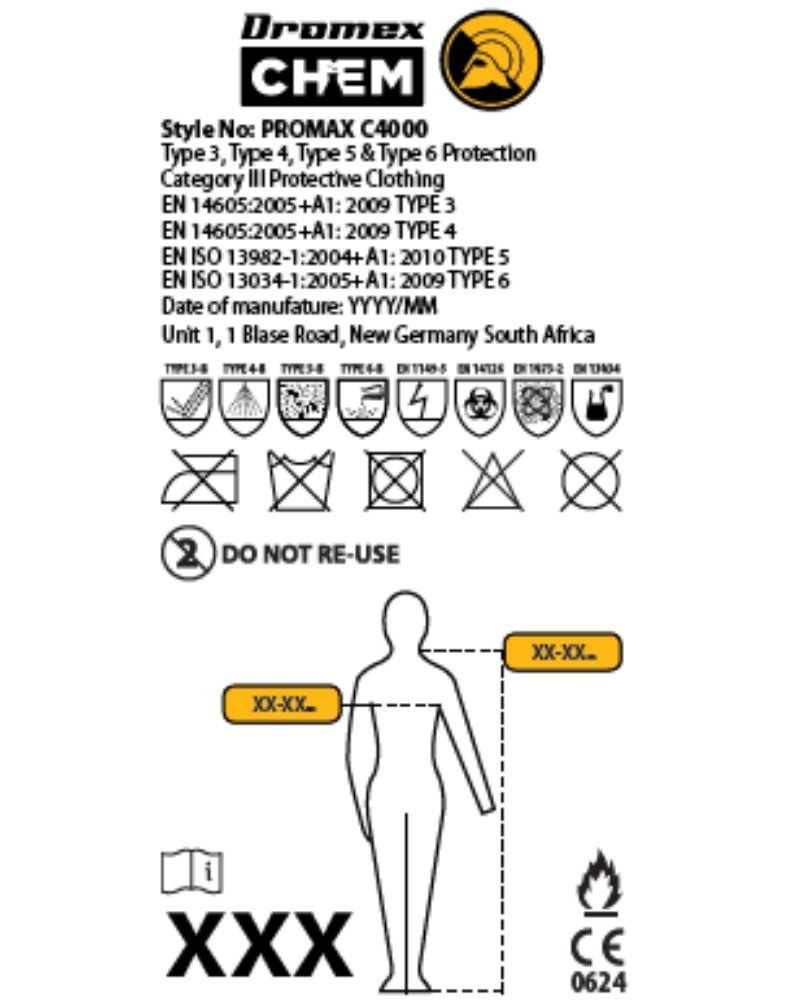

Single‑use garment: dispose of the coverall after use, especially after exposure to contaminants.

Size Chart

| M | Available (manufacturer lists M–3XL) |

| L | Available |

| XL | Available |

| 2XL | Available |

| 3XL | Available |

Customer Reviews

Thandi S. “Used during a solvent spill response—fit was secure and movement unrestricted.”

Mark J. “The knee padding and sealed seams made a long tank‑cleaning shift far more comfortable.”

Ruan P. “Good visibility and dependable sealing. Exactly what we need on site.”

FAQs

Is it suitable for infectious agents? Yes, it complies with EN 14126 for protection against infective agents.

Can I reuse it? No. It is a disposable, single‑use coverall.

Does it protect against particulate radioactive contamination? Yes, it meets EN 1073‑2 (Class 1).

Is it antistatic? Yes, it conforms to EN 1149‑5.

Which environments is it best for? Chemical handling, petrochemical work, spill cleanup, and contaminated sites.

Industries & Applications

- 🧪 Chemical processing & handling

- 🛢️ Petrochemical and oil & gas

- 🚨 Emergency spill response

- 🧼 Contaminated land cleanup

- 🔬 Laboratory and support tasks

- ⚙️ Industrial maintenance

Compliance & Certifications

- EN ISO 13688:2013

- EN 14605:2005 + A1:2009 (Type 3B/4B)

- EN 13034:2005 + A1:2009 (Type 6B)

- EN ISO 13982‑1:2004 + A1:2010 (Type 5B)

- EN 1073‑2:2002 (Class 1)

- EN 14126:2003 + AC:2004

- EN 1149‑5:2008

Why Choose This Coverall

Promax C4000 combines certified protection with practical comfort features, making it a trusted choice for teams that operate in high‑risk environments and need dependable, single‑use protection.