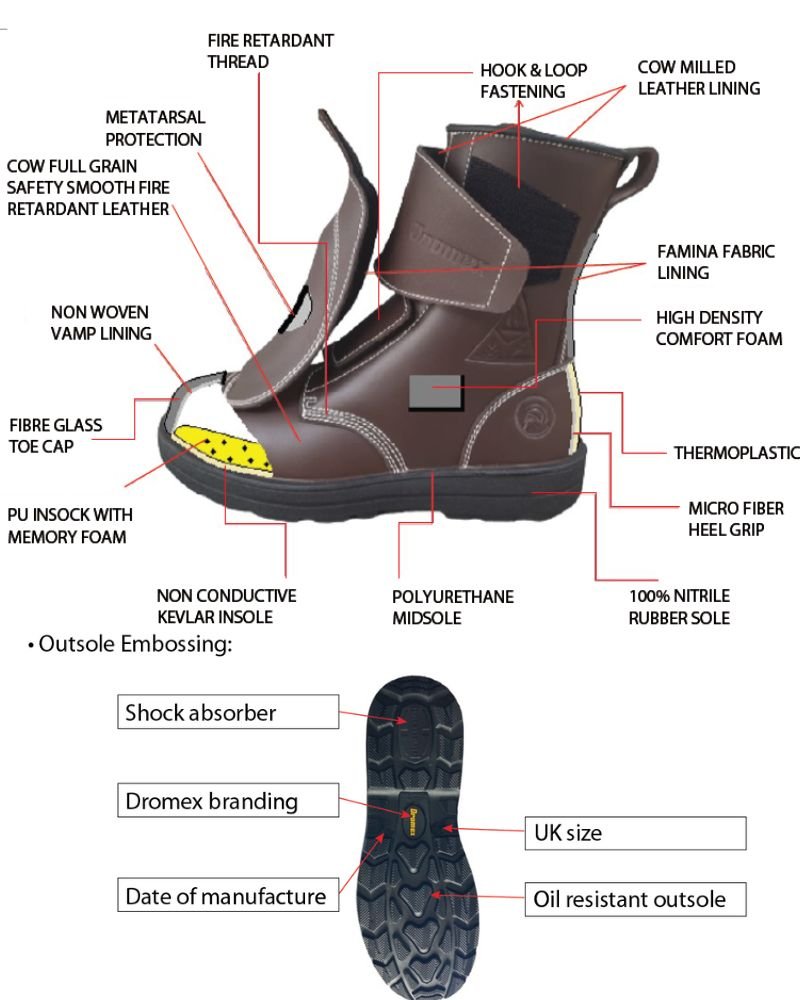

Description

The Dromex® EMPEROR is a high performance, metal free, superior flame retardant and electrical hazard resistant safety boot, incorporating a metatarsal guard designed exclusively for foundry, smelter and welding

work hazards.

The construction of the premium full grain cow leather which is soft, flexible, water resistant, chromium VI free and durable along with a fiberglass toecap and Kevlar midsole, aids in an ergonomic fit, reducing

overall wearer fatigue on the user.

The external metatarsal guard provides added protection to the bridge of your foot from impact and molten metal liquid hazards.

The EMPEROR boots feature the following:

• A slip resistant outsole, SR (Slip resistance on ceramic tile floor with glycerine) rated.

• A PU/nitrile rubber outsole that is lightweight, durable and climate controlling.

• Contact heat resistant outsole at 300°C for 60 seconds.

• The outsole has an energy/shock absorption heel designed for comfort.

• Protection against electrical hazard risks of 18kV in accordance with the ASTM F2413-18.

• A removable and breathable PU and Memory Foam insock deigned for extreme comfort, ideal when standing for long hours.

• An impact resistant fiberglass toecap rated up to 200 ± 4 Joules.

• A Kevlar midsole providing protection from penetrating objects and heat, whilst being lightweight.

• A wider toecap providing extra room and comfort whilst preventing the toes and joints from rubbing onto the toecap.

• Cleated outsole provides additional traction on slippery surfaces.

• A slip on design with large multiple Hook and Loop straps for quick release within seconds in the event of accidental exposure and for easy donning and doffing (putting on and removing boots) when wearing gloves.

Dromex® safety footwear is manufactured using the world class DESMA 24 station, Robotic machine through a direct injection molding process for the upper and midsole and vulcanization producing a high-quality outsole made from PU & Nitrile rubber technologies.

Compliance & Conformity

This Safety Footwear complies with PPE Regulation (EU) 2016/425 and meets the requirements of the European standard

EN ISO20349-1:2017+A1:2020 – Personal protective equipment. Footwear protecting against risks in foundries and welding Requirements and test methods for protection against risks in foundries.

ASTM F2413-18 – Standard specification for performance requirements for protective (safety) toe cap footwear -Electrical Hazard Resistance

Properties Intended to provide a secondary source of electric-shock resistance protection to the wearer against the hazards from an incidental contact with live electrical circuits or electrically energized conductors,

parts or apparatus.

Electrical hazard (EH) footwear is manufactured with non-conductive, electrical-shock-resistant soles and heels. The outsole is intended to provide a secondary source of electric-shock-resistance protection to the

wearer against the hazards from an incidental contact with live electrical circuits or electrically energized conductors, parts or apparatus. It must be capable of withstanding the application of 18,000 volts at 50 hertz for one

minute with no current flow or leakage current in excess of one milliampere under dry conditions.

Specifications

Style: Class I, heat and water resistant leather upper, ankle boot with metatarsal and electric hazard protection.

Materials:

• Toe cap Fiberglass, impact resistant up to 200J ± 4J

• Outsole PU (Polyurethane)/Nitrile Rubber

• Midsole Kevlar

• Upper Flame proof Cow grain leather

• Insole Non conductive Kevlar insole

• Full removable insock Polyurethane with memory foam