Description

Premium Flame-Retardant Safety Boots for Smelters, Foundries & Welders

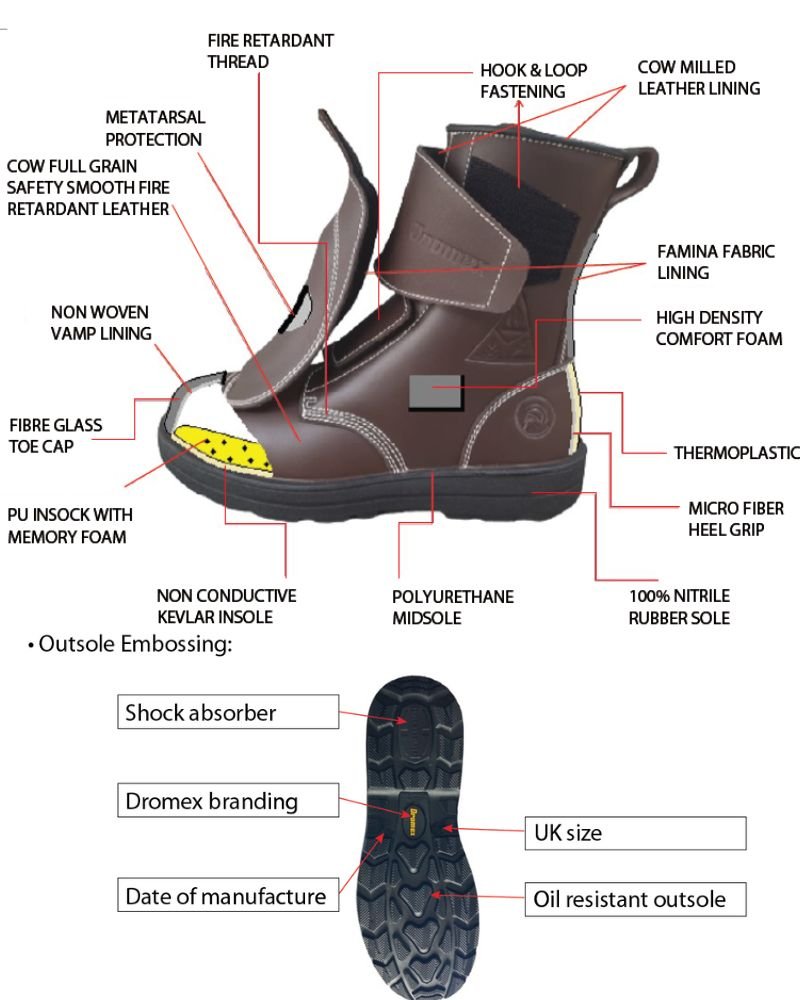

The Dromex® EMPEROR Smelter Boots are engineered for professionals working in high-heat, high-risk environments such as foundries, smelters, and welding operations. Designed for maximum protection and comfort, these metal-free boots combine advanced safety features with ergonomic design to reduce fatigue and enhance performance during long shifts.

Key Features

- Flame-Retardant Full Grain Leather: Soft, flexible, water-resistant, and chromium VI free.

- Fiberglass Toecap: Impact-resistant up to 200 ± 4 Joules.

- Kevlar Midsole: Lightweight, heat-resistant, and puncture-proof.

- External Metatarsal Guard: Shields the bridge of the foot from molten metal and impact.

- Slip-Resistant Outsole: SR-rated for ceramic tile floors with glycerine.

- PU/Nitrile Rubber Outsole: Lightweight, durable, and climate-controlling.

- Heat Resistance: Outsole withstands 300°C for 60 seconds.

- Electrical Hazard Protection: Rated for 18kV in accordance with ASTM F2413-18.

- Shock Absorption Heel: Reduces impact and improves comfort.

- Memory Foam Insole: Removable, breathable, and ideal for long hours.

- Slip-On Design: Large hook-and-loop straps for quick release and easy use with gloves.

- DESMA Robotic Manufacturing: Ensures consistent quality and durability.

Why You’ll Love These Boots

Whether you’re working near molten metal or exposed to electrical hazards, the Dromex® EMPEROR boots offer peace of mind and all-day comfort. The ergonomic design reduces fatigue, while the memory foam insole and shock-absorbing heel keep you going strong. The quick-release straps make them easy to remove in emergencies—because every second counts.

Specifications & Technical Details

- Style: Class I ankle boot with metatarsal and electrical hazard protection

- Upper: Flame-proof full grain cow leather

- Toe Cap: Fiberglass, impact-resistant (200 ± 4J)

- Midsole: Kevlar, puncture and heat resistant

- Outsole: PU/Nitrile rubber, slip and heat resistant

- Insole: Non-conductive Kevlar

- Insock: Removable PU with memory foam

- Compliance:

- EN ISO 20349-1:2017+A1:2020 (Foundry & Welding PPE)

- ASTM F2413-18 (Electrical Hazard Resistance – 18kV)

How to Use

- Slip your foot into the boot.

- Secure the hook-and-loop straps for a snug fit.

- Ensure the metatarsal guard is properly aligned.

- Remove insock to air out after extended use.

Size Chart (UK to CM)

Note: Sizing may vary slightly by brand.

| UK Size | EU Size | Foot Length (cm) |

|---|---|---|

| 5 | 38 | 24.0 |

| 6 | 39 | 24.5 |

| 7 | 41 | 25.4 |

| 8 | 42 | 26.0 |

| 9 | 43 | 27.0 |

| 10 | 44 | 27.9 |

| 11 | 46 | 28.6 |

| 12 | 47 | 29.4 |

| 13 | 48 | 30.2 |

What Customers Are Saying

Cornelius M.

“These boots saved my feet during a molten spill. The metatarsal guard is a game-changer!”

Lerato D.

“I wear them for 10-hour shifts and my feet feel supported all day. Worth every cent.”

Johan V.

“Tough, reliable, and surprisingly comfortable. I’ve recommended them to my whole team.”

Frequently Asked Questions

Q1: Are these boots suitable for electrical work?

Yes, they are rated for 18kV electrical hazard protection under ASTM F2413-18.

Q2: Can I wear these in extremely hot environments?

Absolutely. The outsole is heat-resistant up to 300°C for 60 seconds.

Q3: Do I need training to use these boots?

No special training is required, but always follow your workplace PPE guidelines.

Q4: Are they compatible with welding gear?

Yes, they are designed specifically for welding and foundry environments.

Q5: How do I clean and maintain them?

Wipe with a damp cloth and air dry. Avoid harsh chemicals.

Q6: Are they heavy?

No, the fiberglass toecap and Kevlar midsole keep them lightweight without compromising safety.

Step Into Safety – Built for the Toughest Jobs

Don’t compromise when it comes to your safety. The Dromex® EMPEROR Smelter Boots are trusted by professionals across high-risk industries. Order now and experience the perfect balance of protection, comfort, and durability.

Industries & Workplace Applications

- Foundries

- Smelters

- Welding Workshops

- Steel Manufacturing

- Mining

- Oil & Gas

- Power Plants

- Construction

- Shipbuilding

- Heavy Engineering