Description

Durable Flame-Resistant Workwear for High-Risk Environments

The Dromex® D59 Eskom Spec Utility Flame Jacket and Pants set is a premium, flame-retardant workwear solution designed for professionals working in hazardous environments. Tailored to meet Eskom’s strict specifications, this locally manufactured PPE offers superior protection, comfort, and durability for workers in energy, utility, and industrial sectors.

Key Features

- Flame-Retardant Protection: Treated to resist flame contact and reduce injury risk.

- High Visibility: 50mm silver flame-retardant reflective tape on arms and legs.

- Durable Construction: Triple-needle stitched seams and heavy-duty D59 drill fabric.

- Comfortable Fit: 100% cotton satin weave for breathability and all-day wear.

- Functional Design:

- Jacket with concealed Vizlon zip and press stud closure.

- 2 open waist pockets and 1 mitred flap breast pocket with pen division.

- Embroidered ESKOM logo and “Zero Harm” branding.

- Side slits for better waist fit.

- Metal-Free: Safe for electrical environments.

Why It Matters

When working in high-risk environments, safety is non-negotiable. The Dromex® D59 Eskom Spec Utility set offers peace of mind with its flame-resistant technology and high-visibility features. Whether you’re maintaining power lines or operating in a plant, this gear ensures you’re protected, visible, and comfortable—helping you focus on the job, not the risks.

Specifications & Technical Details

- Style: Metal-free, Eskom pantone navy blue

- Fabric: 100% Cotton, D59 drill, 4/1 satin weave

- Mass: 315gsm

- Reflective Tape: 50mm silver flame-retardant

- Compliance & Conformity:

- SANS 434: Workwear construction standards

- SANS 1387-4: D59 drill fabric

- SANS 1423-1: Flame retardancy (Class B, Category 1)

- SANS 50471: High-visibility clothing

- SANS 1362, 1387-10, 1822, 5278, 10235: Supporting textile standards

- Flame Test Results:

- Ignition time: 20 sec

- Flame propagation: 5mm/s

- Surface flash: None

How to Use

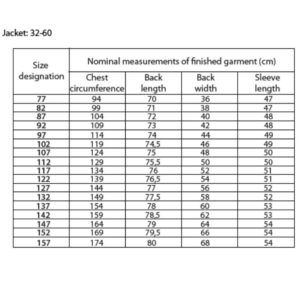

- Select your correct size using the chart below.

- Wear over base layers for optimal comfort.

- Ensure all closures are fastened before entering hazardous zones.

- Follow wash instructions to maintain flame-retardant properties.

Size Chart (UK to CM – Alpha Chart)

| UK Size | Alpha Size | Waist (cm) |

|---|---|---|

| 28 | XS | 71 |

| 30 | S | 76 |

| 32 | S | 81 |

| 34 | M | 86 |

| 36 | M | 91 |

| 38 | L | 97 |

| 40 | L | 102 |

| 42 | XL | 107 |

| 44 | XL | 112 |

| 46 | 2XL | 117 |

| 48 | 2XL | 122 |

| 50 | 3XL | 127 |

| 52 | 3XL | 132 |

| 54 | 4XL | 137 |

| 56 | 4XL | 142 |

| 58 | 5XL | 147 |

| 60 | 5XL | 152 |

| 62 | 6XL | 157 |

| 64 | 6XL | 162 |

Note: Sizing may vary slightly by brand. Always refer to the size chart before ordering.

What Our Customers Say

Sipho M.

⭐️⭐️⭐️⭐️⭐️

“This is the best PPE I’ve used in my 15 years at Eskom. It fits well, feels breathable, and gives me confidence on the job.”

Edwin D.

⭐️⭐️⭐️⭐️

“The reflective tape is a game-changer for night shifts. I feel safer and more visible.”

Cornel K.

⭐️⭐️⭐️⭐️⭐️

“Durable and comfortable. Even after multiple washes, the flame resistance holds up. Highly recommend!”

Frequently Asked Questions

Q1: Is training required to wear this garment?

A: No special training is needed, but users should be briefed on proper wear and care.

Q2: Can I wear this over other clothing?

A: Yes, it’s designed to be worn over base layers for added comfort and protection.

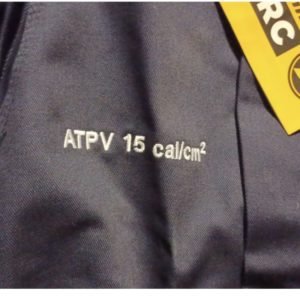

Q3: Is this suitable for welding or arc flash protection?

A: This garment is flame-retardant but not arc-rated. For arc flash protection, use arc-rated PPE.

Q4: How do I maintain the flame-retardant properties?

A: Follow the wash instructions carefully. Do not use bleach or fabric softeners.

Q5: Is this compliant with Eskom’s latest PPE standards?

A: Yes, it meets Eskom specifications and is approved under SANS 434.

Q6: Can I use this in other industries besides Eskom?

A: Absolutely. It’s suitable for any high-risk environment requiring flame protection.

Stay Safe, Stay Visible – Order Your Flame Jacket & Pants Today

Don’t compromise on safety. The Dromex® D59 Eskom Spec Utility Set is trusted by professionals across South Africa. Whether you’re in the field or on the floor, this gear has your back. Order now and gear up with confidence.

Industries & Workplace Applications

- Electrical Utilities

- Power Generation

- Mining

- Oil & Gas

- Construction

- Manufacturing

- Rail & Transport

- Engineering

- Maintenance Services

- Industrial Cleaning